WEFTEC 2022 New Orleans

We are exhibiting our products at this conference in October 2022.

Pipeline Pigging Products specializes in pipeline cleaning services and solutions. We know pipe cleaning pigging very well. Over the years we have cleaned in excess of five million linear feet of piping in a wide range of diameter. We can assist with large and small cleaning projects.

Pipeline Pigging Products specializes in pipeline cleaning services and solutions. We know pipe cleaning pigging very well. Over the years we have cleaned in excess of five million linear feet of piping in a wide range of diameter. We can assist with large and small cleaning projects.

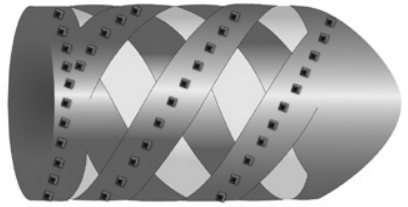

At Pipeline Pigging Products, we stock a full range of pipeline cleaning equipment, which includes poly pigs and launchers, pig trackers, pipe pumps and stoppers.

In order to clean pipelines, we pneumatically or hydraulically propel a series of flexible foam progressive pipe cleaning pigs into the pipeline.

Use this method of progressive pipe cleaning to clean your own pipes:

Isolate the line to be cleaned from the system.

Check to make sure that all valves on the line to be cleaned are open.

Turn on the water to double check the direction of flow.

Run a line size swab to prove the flow and “true size of opening”.

Examine the swab after it has been discharged. Measure its diameter and introduce a coated pig into the line that will just fit the “true” opening. Run a line size swab behind the coated pig to assure a tight seal. Continue this process until a pig is discharged from the pipeline in reusable condition.

Increase the size of the coated pig until the used pig measures the same I.D. as the pipeline being cleaned. For pipes with a buildup of hard scale, such as iron oxide, wire brush pigs can be applied on final passes.

Run a full size swab to sweep out any loosened debris.

Note: These methods are suggested procedures, your particular application may require that you have “technical assistance” in running your cleaning pigs.

Pipe Pigs offers pipeline-pigging products for every application

Pipe Pigs Services designs and manufactures a variety of pipeline pigging products including:

Need help with progressive pipe cleaning pigging? Get in touch with us for more information, equipment or assistance.

Contact us to learn more about our products and what we can offer your company.